DS175HD Disc Manure Spreader

Delilah DS175𝗛𝗗

𝗛𝗲𝗮𝗽𝗲𝗱 𝗖𝗮𝗽𝗮𝗰𝗶𝘁𝘆: 17.5 m³

About this product:

Overview

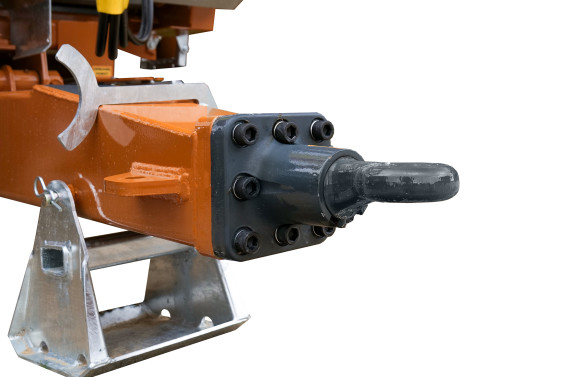

The Delilah DS175HD muck spreader is equipped with a range of advanced features, including a hydraulically operated RT1000 gearbox for consistent material feed and a reverse function for object removal. It has a canopy rubber lining to reduce adhesion, a standard 21-ton sprung drawbar for stability, and twin horizontal beaters with durable Boron steel tips. The heavy-duty HARDOX spinning discs have multi-position Boron blades for precise spread control. 7-teeth sprockets enhance durability, and remote greasing points simplify maintenance. A hydraulic rear canopy door aids in composting and maintenance, while auto chain lubrication reduces wear. Full-width slats prevent material bridging, and a hydraulic slurry door is versatile. The swivel Ø50mm towing hitch aids in maneuverability during towing. These features combine for efficient and durable muck spreading.

Available in 15m3 and 17.5m3 models with a range of options, the Delilah spinning disc spreader is suitable for widespread applications and high-accuracy spreading.

View Standard Features

Options

- Choice of tyres to suit your needs

- Rear drawbar with brakes and electrics

- Electronic bed speed control

- Slurry Door Indicator

- GPS ground speed control with valve block

- Fully automated weighing and recording equipment with GPS

- Weigh cells

- Headland limiter

DS150HD

| Area |

Unit

Metric

Imperial

|

|---|---|

| Heaped fill - ɪɴᴛᴇʀɴᴀʟ ᴅɪᴍᴇɴꜱɪᴏɴꜱ ᴀɴᴅ ᴠᴏʟᴜᴍᴇꜱ ᴍᴇꜱᴜʀᴇᴅ ᴡɪᴛʜ ꜱʟᴜʀʀʏ ᴅᴏᴏʀ. |

15.2 m3

537 cu ft

|

| Level fill |

11.6 m3

410 cu ft

|

| Overall length |

8,475 mm

334"

|

| Overall height |

3,637 mm

143"

|

| Overall width |

2,995 mm

118"

|

| Interior length |

5,700 mm

224"

|

| Interior width at bottom |

1,550 mm

61"

|

| Interior width at top - loading width |

2,125 mm

84"

|

| Interior height |

1,250 mm

49"

|

| Loading height |

2,570 mm

101"

|

| Axle carrying capacity | 16,200 Kg |

| Towing Eye to centre of Axle |

5,943 mm

234"

|

| Axle beam (mm) | 150x150x16 |

| Brake size (Ø x W, mm) | 420 x 220 |

| Standard tyre size | 580/70R38 |

| Rotor Ø (mm) | 610 mm |

| Disc Ø (mm) | 1,100 mm |

| Floor chains (qty x Ø, mm) | 2 x 20mm |

| Floor driveshaft Ø (mm) | 80 mm |

| Floor Drive Torque (Nm) | 6500 |

| Power requirement (hp) | 150 |

| PTO Speed (rpm) | 1000 |

| Tare weight (kg) | 6,120 Kg |

| Heap volume |

3.6(m3)

127(cu ft)

|

| Level fill |

11.6(m3)

410(cu ft)

|

DS175HD

| Area |

Unit

Metric

Imperial

|

|---|---|

| Heaped fill - ɪɴᴛᴇʀɴᴀʟ ᴅɪᴍᴇɴꜱɪᴏɴꜱ ᴀɴᴅ ᴠᴏʟᴜᴍᴇꜱ ᴍᴇꜱᴜʀᴇᴅ ᴡɪᴛʜ ꜱʟᴜʀʀʏ ᴅᴏᴏʀ. |

17.3 m3

611 cu ft

|

| Level fill |

13.7 m3

484 cu ft

|

| Overall length |

8,475 mm

334"

|

| Overall height |

3,637 mm

143"

|

| Overall width |

2,995 mm

118"

|

| Interior length |

5,700 mm

224"

|

| Interior width at bottom |

1,550 mm

61"

|

| Interior width at top - loading width |

2,125 mm

84"

|

| Interior height |

1,500 mm

59"

|

| Loading height |

2,820 mm

111"

|

| Axle carrying capacity |

16,200 Kg

16,200 Kg

|

| Towing Eye to centre of Axle |

5,943 mm

234"

|

| Axle beam (mm) | 150x150x16 |

| Brake size (Ø x W, mm) | 420 x 220 |

| Standard tyre size | 580/70R38 |

| Rotor Ø (mm) | 610 mm |

| Disc Ø (mm) | 1,100 mm |

| Floor chains (qty x Ø, mm) | 2 x 20mm |

| Floor driveshaft Ø (mm) | 80mm |

| Floor Drive Torque (Nm) | 10000 |

| Power requirement (hp) | 180 |

| PTO Speed (rpm) | 1000 |

| Tare weight (kg) | 6,500 Kg |

| Heap volume |

3.6(m3)

127(cu ft)

|

| Level fill |

13.7(m3)

484(cu ft)

|

Downloads

Find your nearest dealer

From our international network

RW Product Guide

RW Product Guide

Product Manual

Product Manual